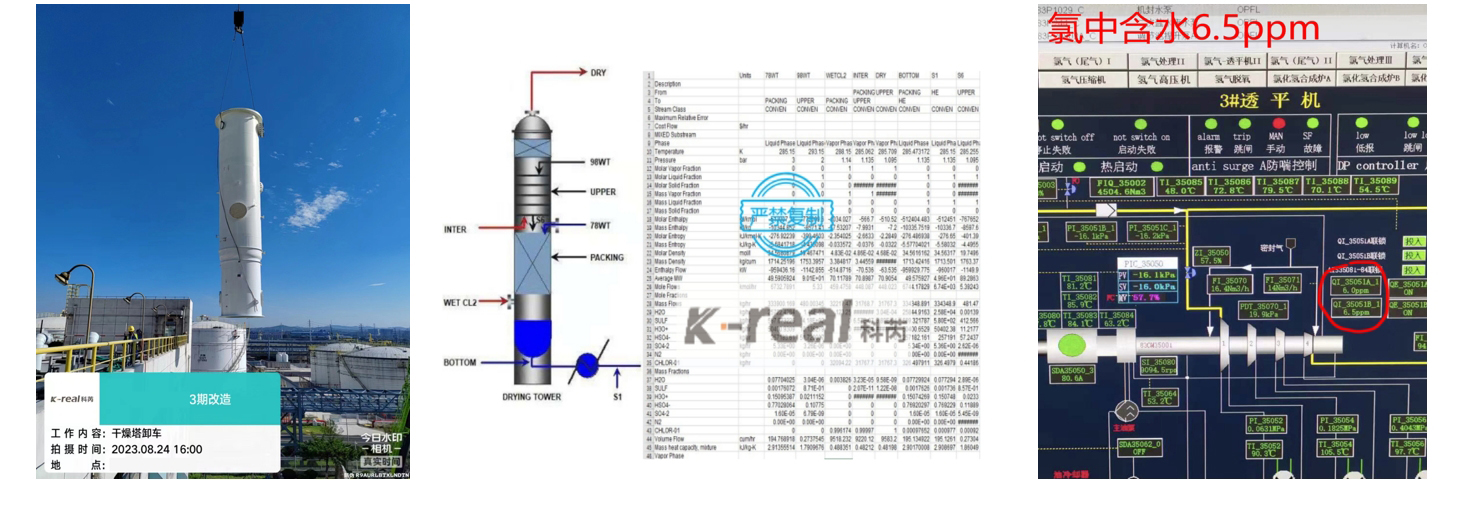

So far, the company has implemented a number of engineering cases for chlorine gas treatment system. The chlorine gas drying section adopts the high-efficiency single-tower process. At present, the capacity of a single set of this technology can reach 400,000 tons (as 100% caustic soda)/year. As many sets have been running stably so far, the moisture content in chlorine gas is all less than 10ppm. Meanwhile, the acid consumption, energy consumption and intelligence are all better than the traditional two-tower and three-tower process, which has been unanimously recognized by the users.

Water concentration in chlorine is less than 10ppm in one plant located in Shandong Province with capacity in 250kt per year

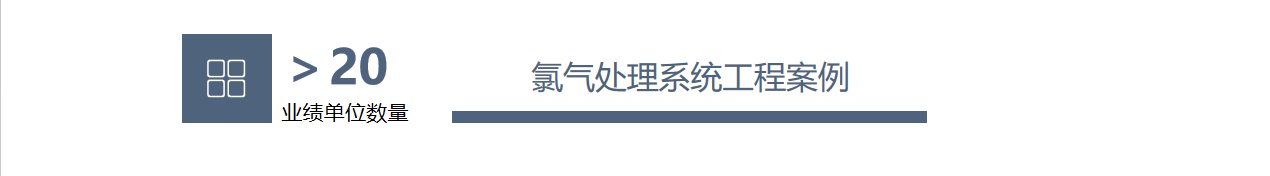

Three towers process was upgraded into one-tower technology in phase 3 upgrading project in one plant located in Shandong province. Capacity was increased by 25 percent without changing the diameter of the tower. At full capacity, pressure drop of bubble-cap section and packing section was 4.8kpa and 0.3kpa, separately, and the total pressure drop through the tower is 5.1kpa and water content in Cl2 is only 6.5ppm. Technology indication such as water concentration, pressure drop and consumption of sulfuric acid is better after upgrading.

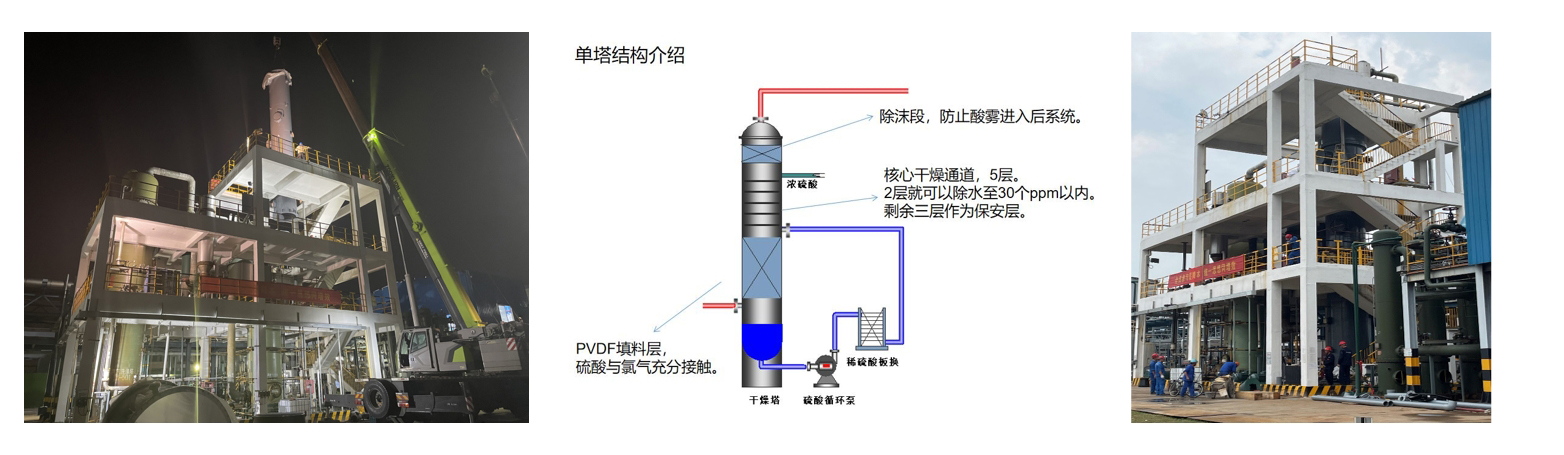

One-tower unit with capacity of 160kt used in both phase 1 and phase 2 plant of an enterprise

Originally Cl2 drying tower system( in three towers process) was upgraded into one-tower chlorine drying with high-efficiency provided by our company in phase 1 and phase 2 reproduction of the plant of a chemical enterprise in Inner Mongolia. And the water content in chlorine was stabilized at about 10ppm, and the saved area in two spans was used for sulfuric acid dechlorination unit.

Replacement of damaged equipment corrosion PVC/FRP

Three-tower process was originally used in drying section by one plant in Chongqing, and the material packing was PVC/FRP. There was corrosion after operating in a few years. One-tower technology was selected using the opportunity of turn-around in early 2024.

Assemble was completed within 8 hours for a plant with capacity of 120kta caustic soda in a company in Jiangsu

The capacity of electrolyzer was expanded in one plant in Jiangsu province and the equipment foundation in the plant remained unchanged. By using one-tower drying unit of our company, the capacity was improved, and the size is also decreased than the original system. The original tower was dismantled at 16 o'clock in the afternoon, and the new unit was assembled completely at 24 o'clock.